The use of wheel cleaning brushes are particularly useful in applications such as the aluminum extrusion process, turbine blades, aluminum wheels, transmission valve bodies, bench grinders, robotic finishing equipment, hand-held grinders and pump gears. The circular shape is ideal for hard to reach areas, and wheel brush sizes range anywhere from small diameter wheel brushes to large wide face wheel brushes that can be used individually or gang-mounted. Read More…

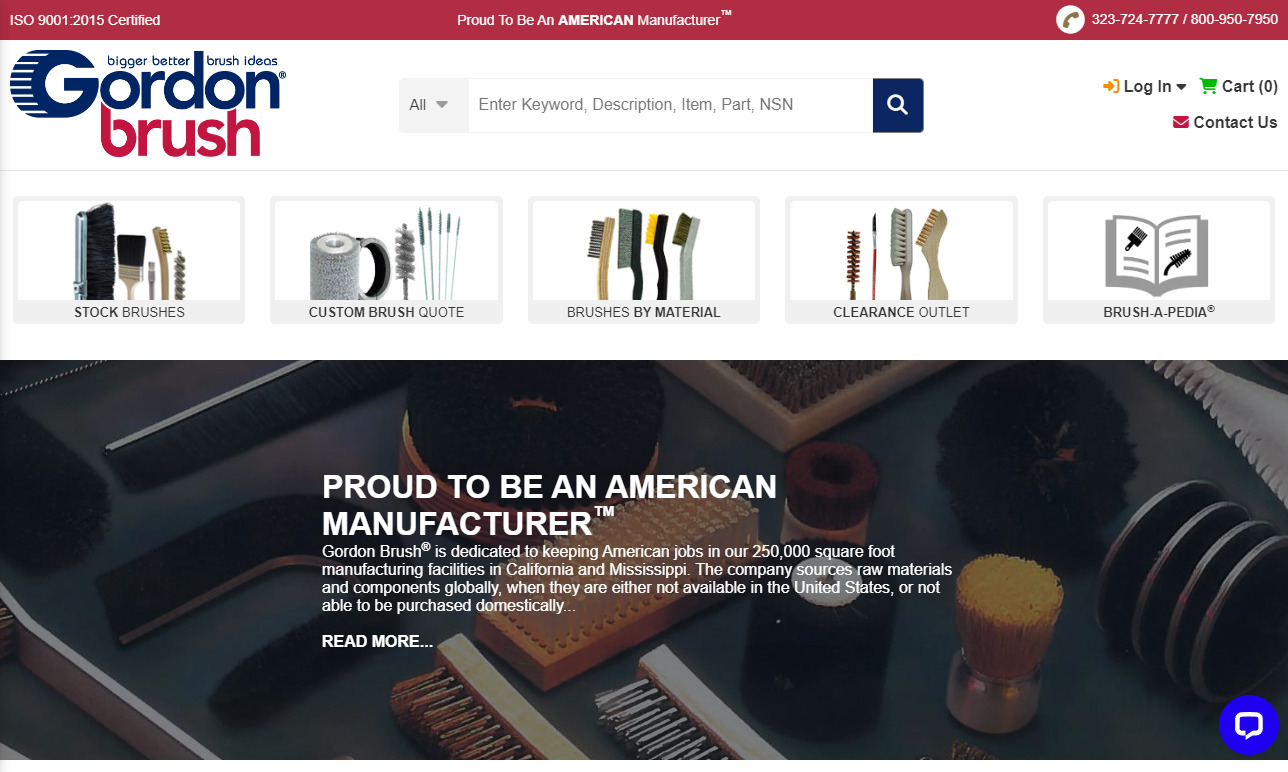

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

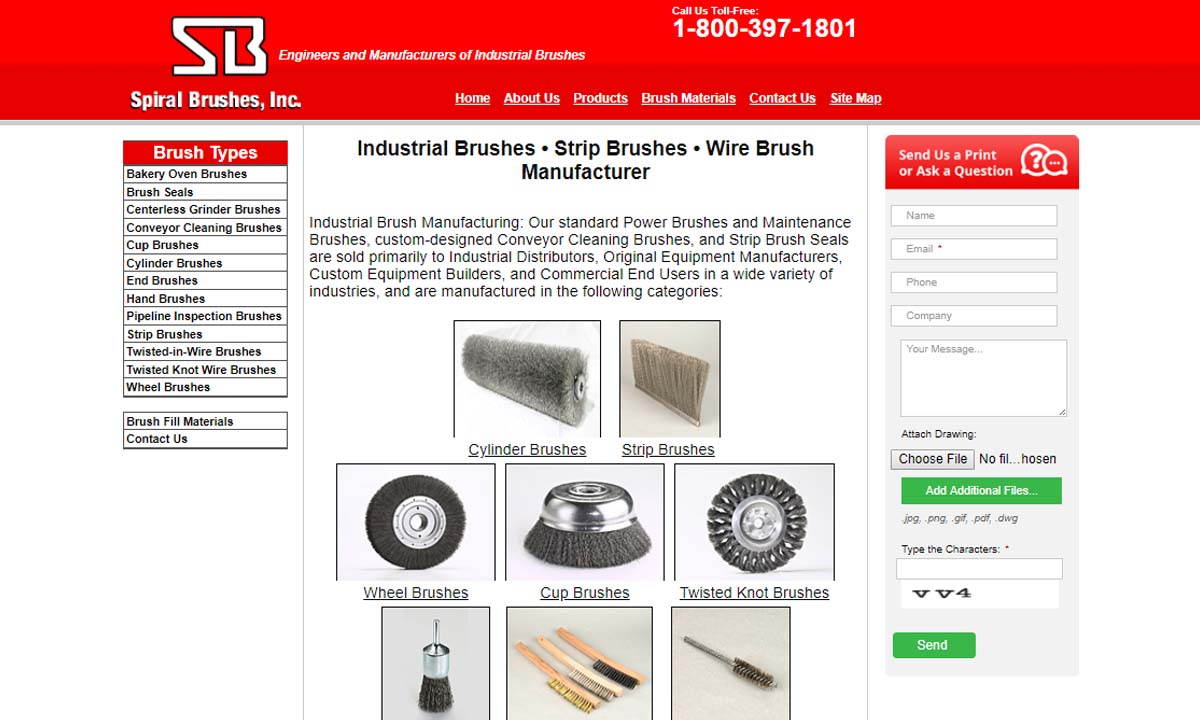

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Wheel Brush Manufacturers

Typical industries that utilize wheel brushes include automotive, ventilation, refrigeration, aerospace, medical, optics, textiles and electronics. Cup brushes are used in similar applications as wheel brushes and are basically strip brushes that are looped laterally to form circular shapes, which are then inserted and adhered into metal cups.

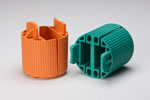

The basic wheel brush configuration is that of the wheel hub and the bristles. In the center of the wheel hub is an arbor hole, which is the central hole in a wheel brush through which the arbor fits. An arbor is a spindle or shaft that supports a gear or wheel and an arbor hole is typically either cast or reamed into the wheel hub.

The most common method of construction for wheel brushes is to place a piece of material over holes that are either drilled or molded into the wheel hub, securing that material with a metal staple at each hole, folding the material over and creating bristles. The three materials most often used in wheel brushes include wire, impregnated wire and abrasive nylon. Wire wheel brushes can be made in a crimped or knotted style.

The crimped style allows the wire to break cleanly as it wears, increasing the longevity of the brush. The knotted, or twisted, style uses straight wire that is twisted to various specifications in order to progressively increase brushing action control and cutting action aggressiveness.

In impregnated wire wheel brushes, the wire bristles are impregnated with a polymer such as polypropylene for additional abrasiveness. Typical metal wire materials used in wheel brush applications include steel, stainless steel, bronze, aluminum, nickel silver, copper or titanium. In abrasive nylon wheel brushes the nylon bristles are also impregnated for increased abrasiveness, only the nylon is impregnated with grains of materials such as silicon carbide, diamond and aluminum oxide.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services