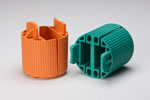

Rotary Brushes

A rotary brush is used with a machine that spins it on a cylinder or on a ring with the bristles pointing downwards. These brushes can be found on automatic shoes polishers, street cleaners, conveyor belts and more. In any industry where heavy duty cleaning equipment is needed, there is usually a piece of equipment that is fitted with a series of durable rotary brushes to get the job done. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

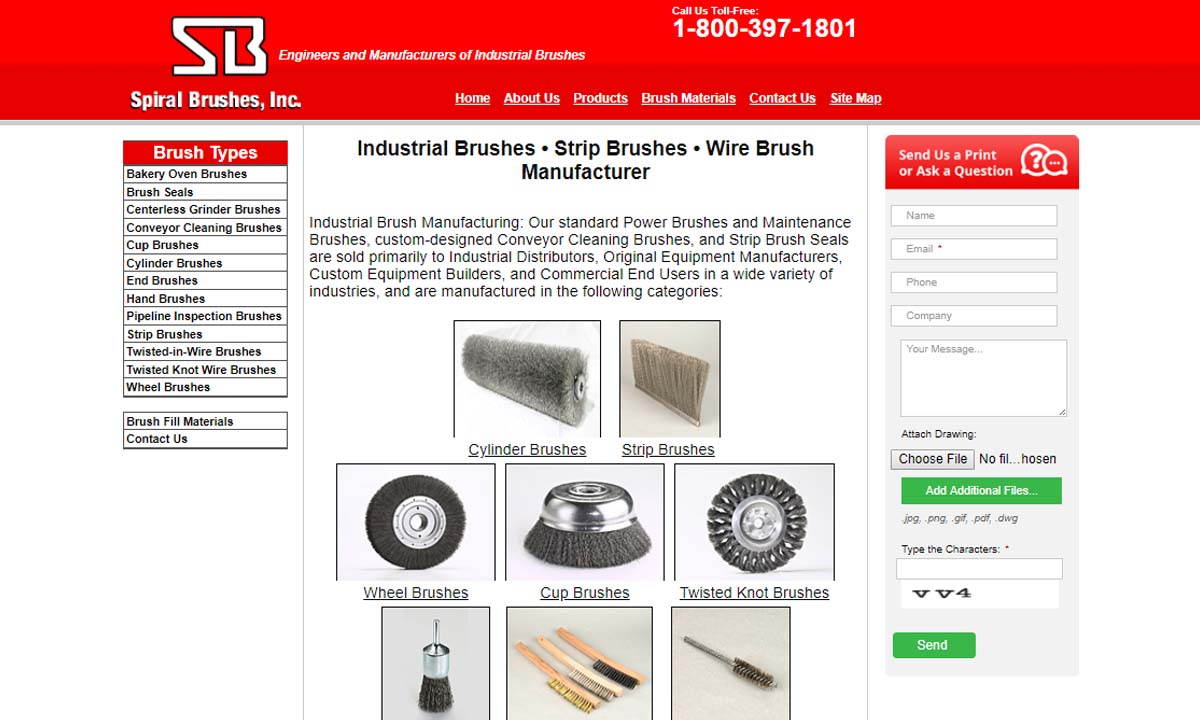

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Rotary Brush Manufacturers

Rotary brushes can be manufactured in a variety of configurations and they are usually made to be replaceable once the bristles wear out from too much use. As mentioned above, rotary brushes are used on most street sweeping machines to remove dust and debris from the street. A series of rotating brushes points downward on the front of the vehicle, gathering up dirt as the brushes spin and make contact with the pavement. A street sweeper will usually have gutter brooms on the outside that spin inward, guiding the dirt to a large rotary brush that sweeps it into the street sweeper's vacuum system.

Very large rotary brushes mounted on a long cylinder are also used to clean runways at airports. A runway sweeper removes any unwanted dirt and debris from the surface of the runway, reducing the chance of accidents or other complications during takeoff and landing. A rotary brush can also be made using stainless steel wire for heavy duty cleaning and deburring applications.

When a rotary brush is mounted on a conveyor belt, it is typically used as part of an automated cleaning process. Parts or complete products are moved beneath the rotary brush along the conveyor belt and they are scrubbed as they come into contact with it. One example of this is in potato processing and packaging.

After the potatoes have been sent through a water wash they are moved under a rotary brush that removes any gritty dirt from their surface before they are dried off and packaged. Over time the bristles of the brush will wear down and it will need to be replaced in order to clean effectively in whatever application it is being used for.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services