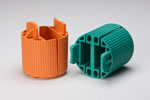

Power Brushes

Power brushes are metal or abrasive nylon filament brushes used to deburr parts during initial phases of the surface finishing process. Designed for precision cutting action, power brushes are mounted in several different shapes that achieve specific precision deburring; wheel, cup, end, wide face cylinder and internal twisted-in wire are the most common power brush configurations. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

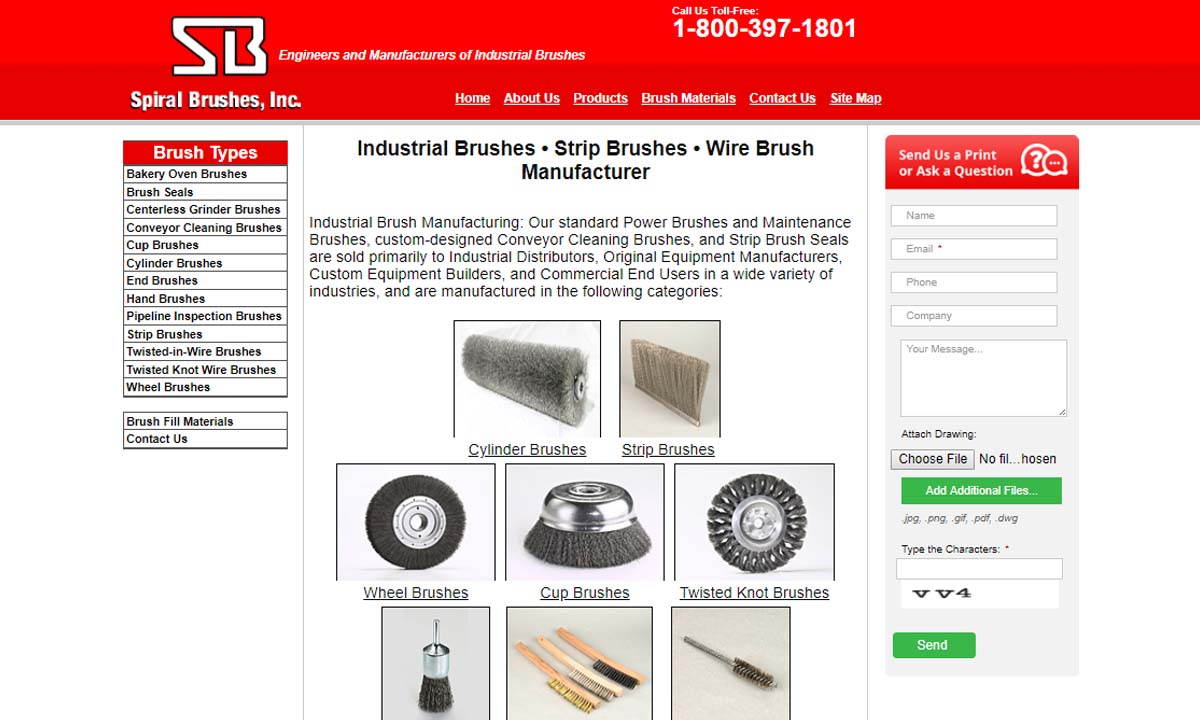

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

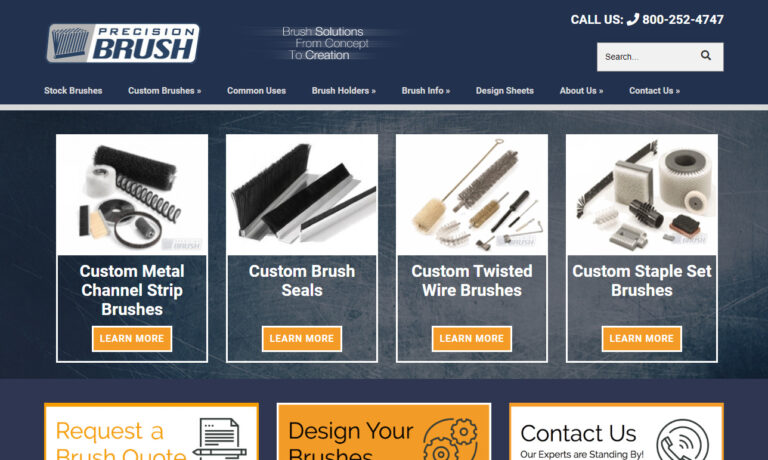

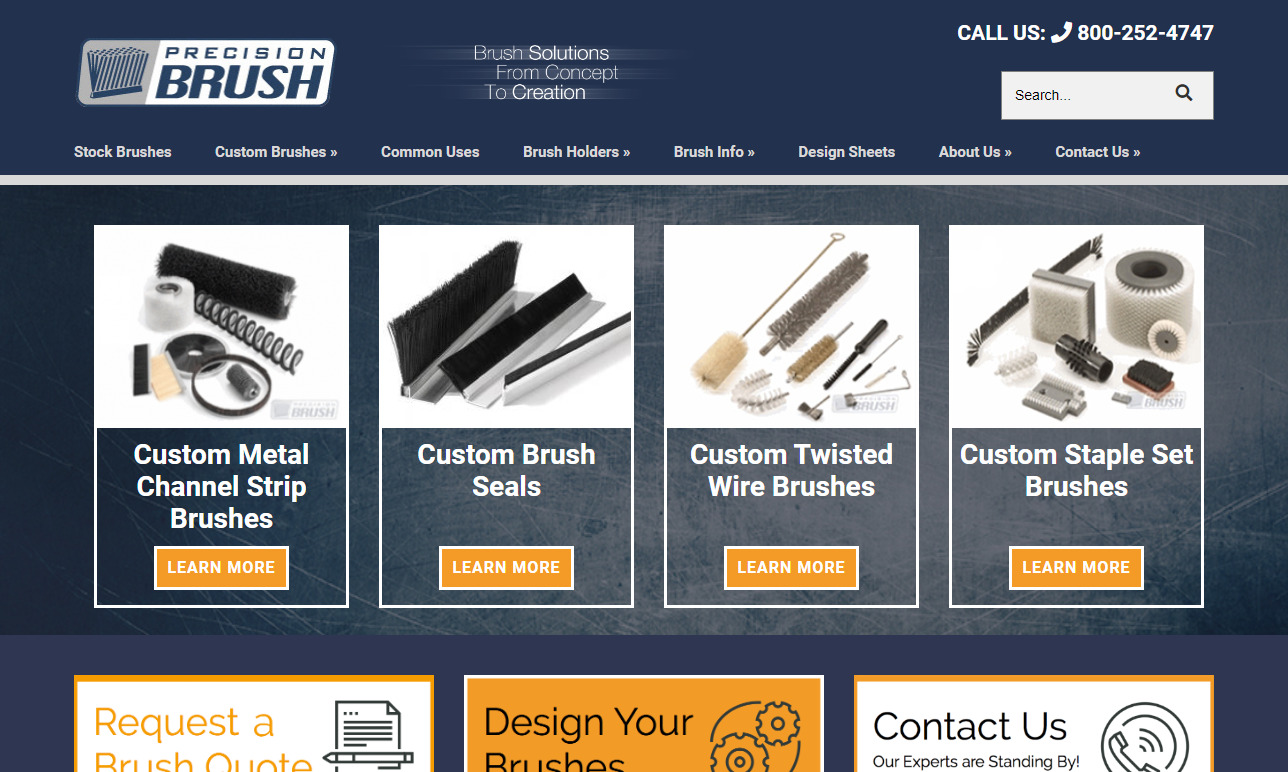

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Power Brush Manufacturers

Fill material, or "filament," is crucial in power brushes, since many industrial processes depend on the ability of a power brush to properly remove burrs and sharp edges from parts so they can perform uniformly and safely. Most power brushes have crimped steel, stainless steel, bronze or brass wire filament; only the tips of the brush's wires have the ability to cut, and as the brush is used the wires break and form new cutting tips, a process that is aided by crimping the wires.

Nylon abrasive filament is also used in many applications that require finer or non-metallic deburring. This material is made abrasive by impregnating nylon with silicon carbide, aluminum oxide, or polycrystalline diamond abrasive grit, which, depending on the size of the grit, can achieve various levels of cutting, deburring, blending or polishing.

Both metal and abrasive nylon filaments may be "encapsulated" in an elastomer coating to amplify cutting capacity. With all the different types of configurations available, power brushes can provide surface conditioning solutions for parts of virtually any size, shape and material.

Power brushes can be used for metal deburring; removing rust, paint scale, or other coatings; gear and thread cleaning; surface preparation; cleaning; finishing and weld blending. They work on most materials, including aluminum, steel, carbide, plastic, wood and glass.

Alternatives to deburring power brushes are deburring machinery such as tumblers, vibratory finishers and multi-process deburring equipment. These machines are generally effective, but they must usually be purchased as large units, which are far more costly than power brushes, which can be attached to a manufacturer's pre-existing equipment or modified to fit an already constructed assembly line.

Power brushes achieve uniform surface conditioning when used properly, and they offer a cost-effective solution for industrial deburring and surfacing.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services