Cleaning Brushes

Cleaning brushes are vital components of industrial manufacturing processes that involve cleaning. Consisting of bristles connected to a handle, cleaning brushes are more useful for abrasive cleaning than other types of cleaning equipment, such as sponges. Cleaning brushes are also able to reach more areas with difficult accessibility. In industrial applications, cleaning usually involves processes such as rust or dirt removal, thread cleaning, removing metal chips, bore cleaning, scraping and dusting. Read More…

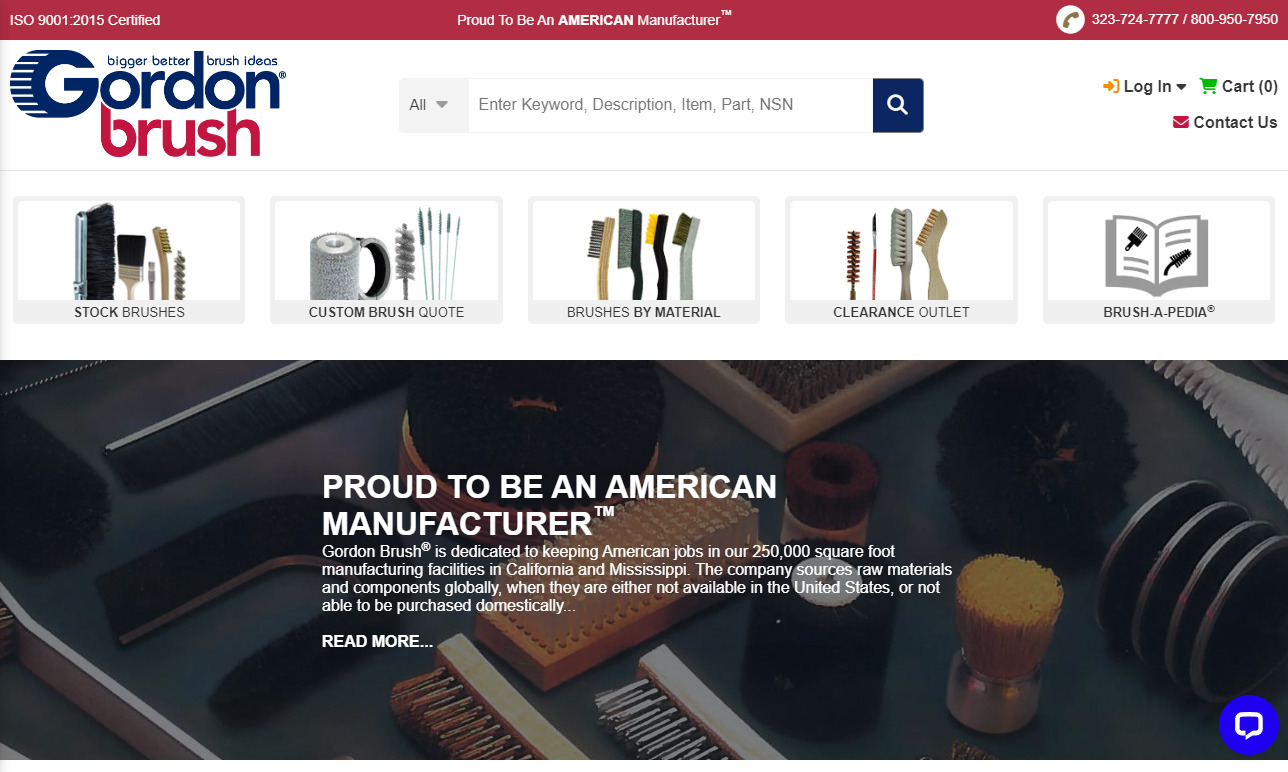

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

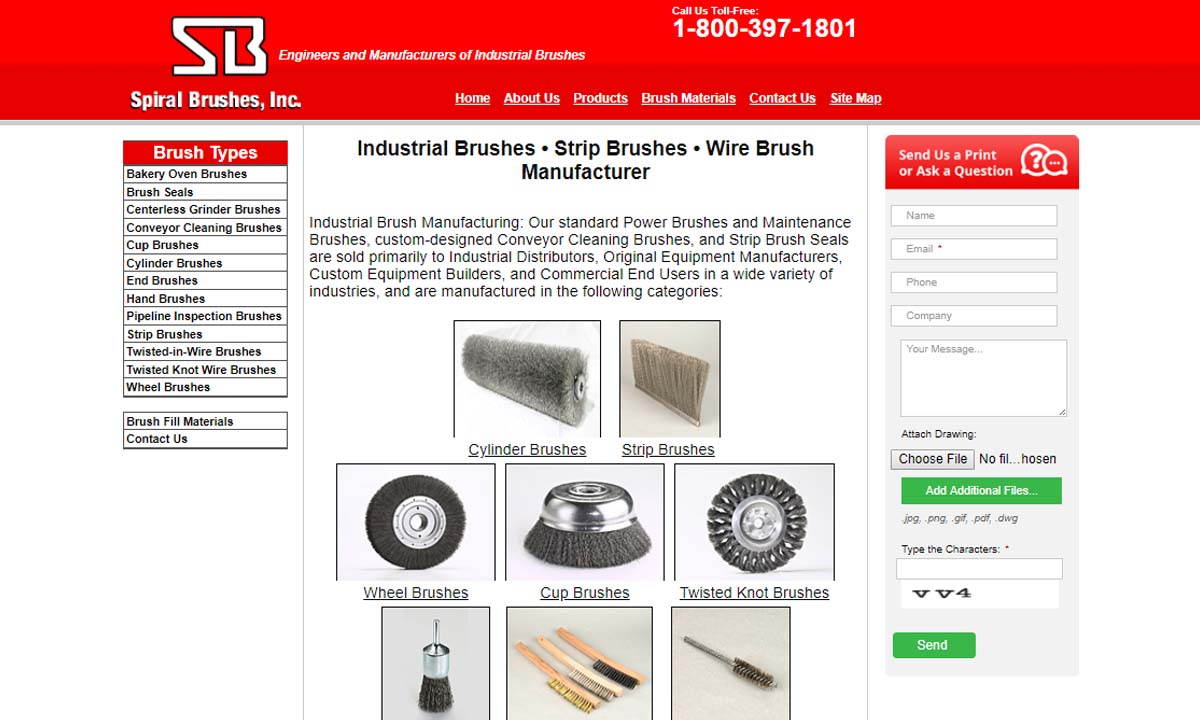

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

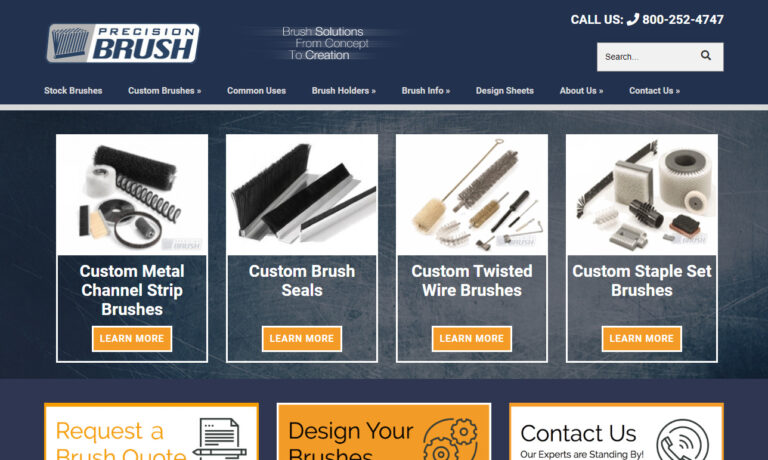

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Cleaning Brush Manufacturers

Able to be used in both heavy duty and lighter tasks, cleaning brushes, such as brooms and cleanroom brushes, have no substitutes in the industrial manufacturing world, and are a vital part of many processes. Almost all industries require the use of cleaning brushes; some examples include textile, food processing, pharmaceutical, electronics, commercial, automotive, aerospace, semiconductor and medical.

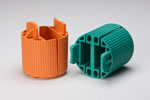

There are two main types of cleaning brushes: twisted-in wire brushes and bristle brushes. Twisted-in wire brushes are made by taking a length of wire doubled over, placing the bristles in between the top and bottom of the doubled over wire, and twisting it up similar to a rubber band. The piece of twisted wire is most commonly made from galvanized steel, stainless steel, aluminum or brass.

Bristle brushes are made by placing a piece of material over holes that are either drilled or molded into a block and securing that material with a metal staple at each hole, folding the material over and creating bristles. The handles in bristle brushes are typically made of wood or injection molded plastic such as polypropylene.

Within the two main types of cleaning brushes, there are many varieties of application-specific brushes such as tube brushes, bottle cleaning brushes, duct cleaning brushes, flask brushes, decanter cleaning brushes and utility brushes. One of the most important aspects for application-specific cleaning brushes is the type of bristle materials used.

Cleaning brush bristles are constructed from a variety of natural and synthetic fibers, including nylon, horsehair, polyester and polypropylene; in fact, many types of polypropylene are used, including closed cell foam and non-woven. However, they may also be made from metals such as galvanized steel, bronze, brass and stainless steel for intensive industrial cleaning applications.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services