Strip Brushes

Strip brushes are long, thin brushes used for a variety of conveyor product cleaning, sealing and surfacing applications in industrial, commercial and some consumer product contexts. Sometimes referred to as channel back brushes, strip brushes can be composed of natural, polymer or metal bristles securely clamped by aluminum or steel channels. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

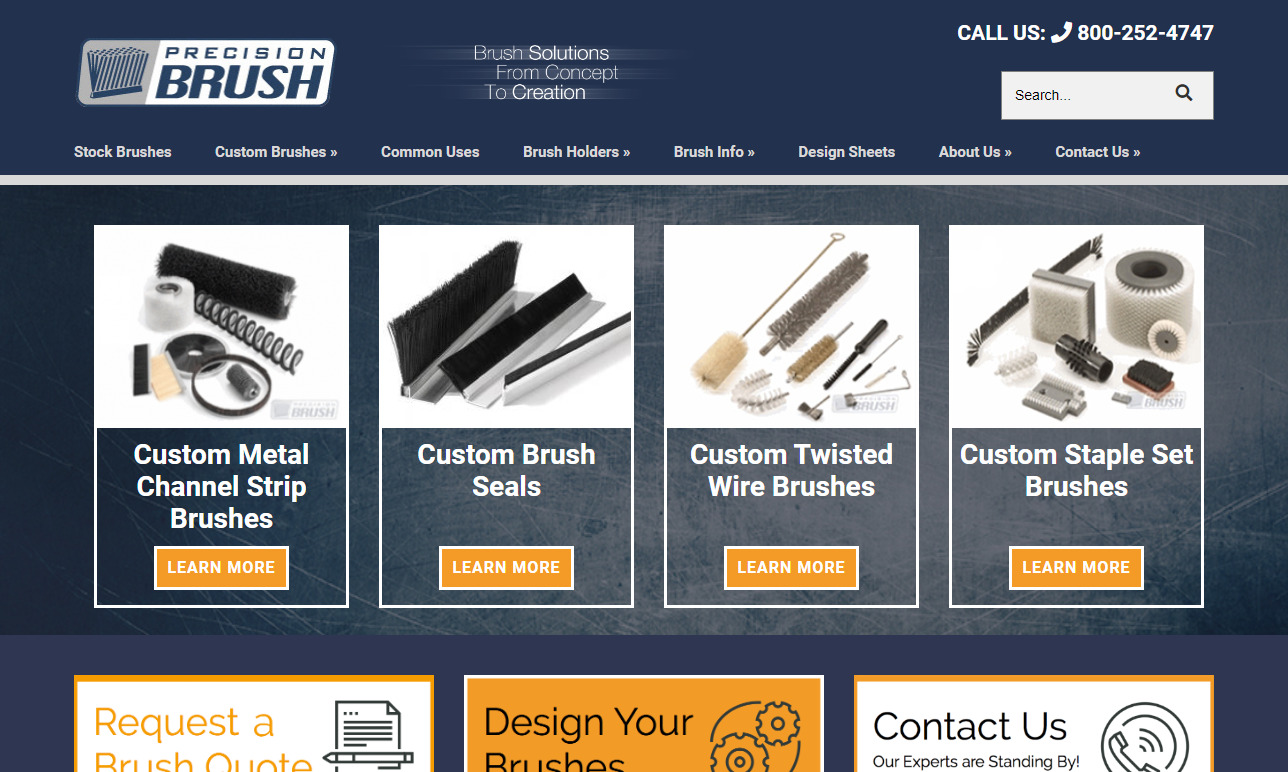

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Strip Brush Manufacturers

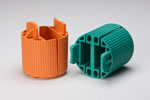

Strip brushes are widely used throughout many industries. They can be coiled to form cylindrical coil brushes, outside disks, inverted disks and cup brushes. Other types of strip brushes can be designed to seal doors, windows, conveyor edges, cleanroom doors and other cracks and openings that require a flexible seal. A strip brush's properties and configuration determine how it will be applied.

Fill material, bristle length, channel size and length all affect a strip brush's performance. Straight strip brushes are often used on conveyor belts for sweep cleaning, product guiding and sorting as well as in sealing and guarding applications, such as vehicle spray guards.

Coiled strip brushes, disks and cup brushes are also used frequently in conveyorized processing for cleaning, surface roughening, dusting, sorting, washing food products, lint brushing, static dissipation, pipe cleaning, textile felting and surface finishing. Metal-bristled coil and cup brushes are often used at high speeds for deburring, finishing or polishing. Strip brushes wound into tight coils are called cylinder brushes, a common cleaning and surface finishing tool.

Nylon is one of the most common fill materials used in strip brushes, since nylon offers superior abrasion resistance, bend recovery and flex fatigue recovery. Sealing strip brushes and many coiled cylinder brushes are made from various lengths of black nylon.

Other strip brushes can be made of polypropylene, polyester and abrasive polymers embedded with silicone carbide particles. Metal is sometimes used as a strip brush bristle material in applications in which an abrasive brush is needed, and animal hair is sometimes chosen as a bristle material for strip brushes used for polishing and cleaning, but the use of animal hair bristles is low compared to other materials because of its expense.

Strip brushes are among the most versatile industrial brush varieties because of the wide range of shapes they can take. A strip brush can be as simple as a straight strip used to seal the gap between a door and its frame, or it can be mounted to a tube along with several other strip brushes to form a power brush attachment. They can be twisted around to form spiral brushes, and they can bent into a circle and attached to form a circular brush.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services