Conveyor Brushes

Conveyor systems are an integral part of the industrial world. In primitive use since the late 19th century, conveyor belts are perhaps best known as the technology that revolutionized the automobile industry when Henry Ford introduced them at the Ford Motor Company in 1913. The longest conveyor belt in the world is in the Western Sahara, measuring 61 miles long. For these systems to run smoothly and efficiently, conveyor belt cleanliness is of the utmost importance. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

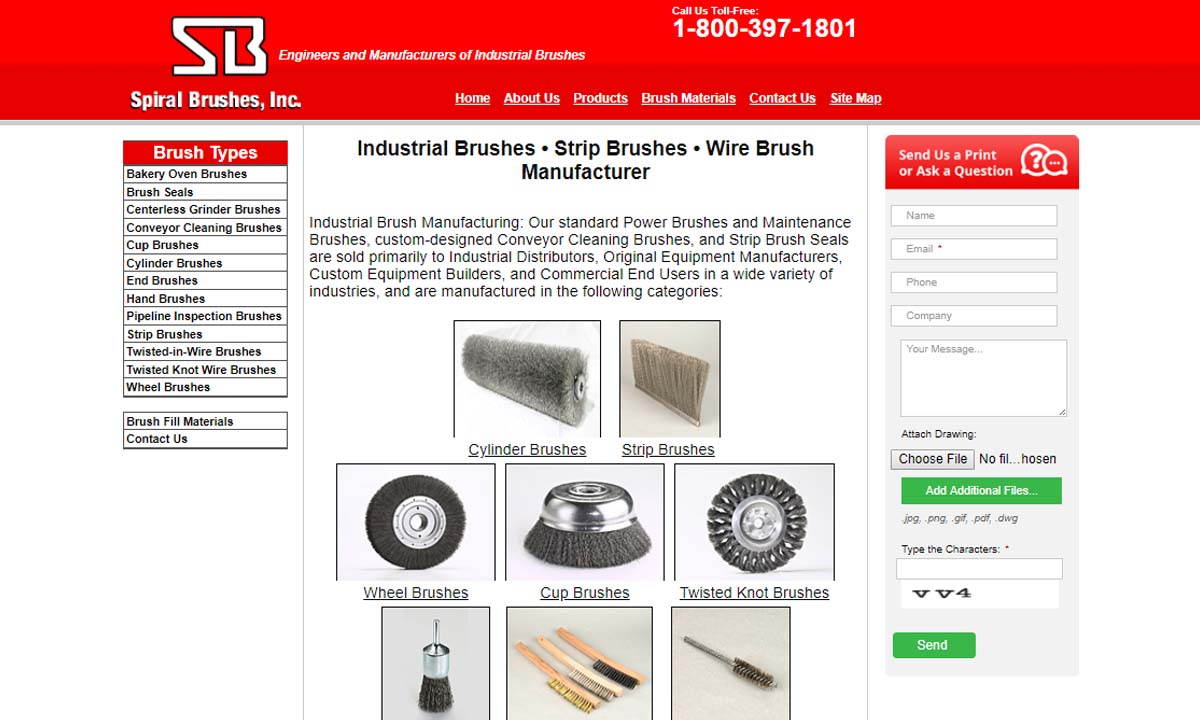

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Conveyor Brush Manufacturers

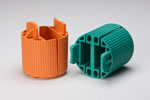

There are a few types of conveyor belt cleaners, one of them being the brush. Conveyor brushes are a secondary cleaner that can normally be used on any type of conveyor belt, though they are particularly well-suited to nonskid and cleated applications. Tools that can either be stationary or rotary, conveyor brushes can be positioned so that they contact the belt very lightly. This prevents them from wearing against belts or other raised belt components.

Conveyor brushes take many forms, in order to clean a variety of materials, like powders and dusts. Such forms include spiral coils, spiral wound on core, and strips and scrapers. Each of these conveyor brushes has a different strength. Spiral coil brushes are lightweight and somewhat universal, used with a wide range of RPMs, sizes, materials and densities. Thus, this brush, which is often available with an installation kit and mounting shaft, meets the needs of a large group of applications.

When deciding on the use of conveyor brushes for a project, several factors must be taken into consideration. The first factor is mounting location. A conveyor cleaning brush should be installed on the outlet end of the conveyor, after and below the head roller or rollers.

Additionally, the brush should be mounted in proximity to a support roller for consistent brush surface pressure. The second factor to consider is design width and diameter. A conveyor brush should have enough room that, when installed, it is wide enough to overlap each side of the belt surface by half an inch.

This ensures complete coverage and accommodation of normal belt weave. The next thing to consider is size and selection of fill material. After that, a potential customer must consider brush density. Then, he or she must consider refillable versus replaceable and integral versus removable shaft. Finally, a customer must consider operating size and speed.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services