AA Abrasives

AA AbrasivesRequest A Quote

Philadelphia, PA | 215-925-6367AA Abrasives is a reputable and renowned company specializing in the manufacturing of brushes and abrasive products. With a strong presence in the industry for over several decades, AA Abrasives has established itself as a leading provider of high-quality brushes and comprehensive service capabilities. At the heart of AA Abrasives' operations lies their brush manufacturing division, where they offer an extensive range of brushes designed to meet the diverse needs of various industries and applications. Whether it's for industrial, commercial, or household use, AA Abrasives provides a comprehensive selection of brushes tailored to specific requirements. Their product line encompasses a wide range of brush types, including wire brushes, abrasive brushes, cup brushes, wheel brushes, and more. AA Abrasives excels in developing custom brush solutions, leveraging their expertise and experience to meet the unique requirements of their clients. Their team of skilled engineers and designers collaborate closely with customers to design and manufacture brushes that precisely match their specifications and applications. With advanced manufacturing techniques and state-of-the-art equipment, AA Abrasives ensures that their custom brushes exhibit exceptional quality, performance, and durability. The company's manufacturing capabilities are a testament to their commitment to excellence. AA Abrasives utilizes cutting-edge technology and machinery to produce brushes that meet the highest industry standards. They combine traditional craftsmanship with modern automation to achieve optimal brush consistency, precision, and functionality. The company's manufacturing processes are streamlined, efficient, and environmentally conscious, ensuring minimal waste and environmental impact. AA Abrasives' service capabilities go beyond brush manufacturing. They offer a comprehensive range of value-added services to meet the diverse needs of their customers. These services include product design and development assistance, where AA Abrasives collaborates with clients to optimize brush performance and functionality. Additionally, they provide technical guidance, application support, and post-sales assistance to ensure that customers derive the maximum benefit from their brushes. Quality control is a top priority for AA Abrasives. They adhere to rigorous quality assurance protocols at every stage of the manufacturing process, from material selection to final inspection. Each brush undergoes thorough testing and inspection to ensure its compliance with industry standards and customer expectations. AA Abrasives' commitment to quality is reflected in the reliability, durability, and performance of their brushes. As a customer-centric organization, AA Abrasives places great emphasis on building strong and lasting relationships with their clients. They prioritize open communication, understanding customer needs, and delivering exceptional value. With their extensive distribution network and efficient logistics, AA Abrasives ensures timely delivery and competitive pricing, enhancing customer satisfaction and convenience. In summary, AA Abrasives is a trusted brush manufacturer offering a diverse range of high-quality brushes and comprehensive service capabilities. Their commitment to excellence, advanced manufacturing techniques, and customer-centric approach have positioned them as a preferred partner for businesses across various industries. Whether it's for industrial applications, surface preparation, or general cleaning, AA Abrasives is dedicated to providing brushes that deliver superior performance, durability, and value.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

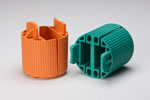

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services